I have seen this technique several times on Pinterest and decided to try it. Mainly due to the fact that I always have trouble with small hems. I even bought the rolled hem foot which I can only get good results 1/2 the time. I was working on a shirt for my nephew and wanted a nice tight, clean, small hem and of course it was not a straight hem. The posts have talked about using tear away stableizer, frayed fabric, tissue or wax paper, one person even suggested using adding machine paper because it was thin enough to remove easily and still support the hem.

So I decided to put my own spin on it and because I did not have the other stuff. I used some print paper, a ruler and a rotary cutter to make 1" strips.

I experimented with different widths of course, too small and you can not get a clear tear away, too big is a waste and hard to maneuver around curves. 3/4" actually works but I wanted to get the most use out of each piece and with a 1" width I can actually recycle and use the other side for another project.

On the right side of the fabric line up the paper with the edge of the material. I have the need set all the way to the right to get as small a seam as I can. If you need is not adjustable just move the fabric over until you have the distance from the edge you need.

I do not bother with pinning the paper I just feed the next piece in as I go. As I get closer to the curves I will tear the paper to allow me to adjust around the curve. You do not even need to tear completely across just enough to bend.

Once the whole hem is done it should look like this.

Now comes the pressing, Make sure the Iron is not too hot especially if you are using wax paper. I am folding the paper out so that the sewn edge goes underneath toward the back of the garment.

You will notice that I used a very small stitch (little over 1) because the closer the stitch the easier it will be to tear away.

Now that it is completely ironed you will fold again towards the wrong side of the material. I ironed as I did this then placed a couple of pins. I think the ironing the edge made it easier. You can already see how small and clean the hem is going to be.

You will notice the needle is in the same position which puts it just on the edge of the fold.

This is what you should have when finished. now comes the fun part.

I found it easier to pull towards you and out away from the seam at the same time with a quick tug. Any bits and pieces of paper can be pulled later or use a damp cloth to clear it up.

When finished you have the following hem with maybe 3/16" of paper left in the seam. So not difficult and gives you such a nice finish better then most methods and not needing to use a lot of pins. I have already washed the shirt and did not feel any pilling probably because of the narrowness and the fact that it has no place to go. What will happen in the long run not sure of but since my family tend to hard their clothes it should not matter anyway.

We are trying to survive in a combined household with pay cuts, children, dogs, lots of dogs, invalids, stubborn people and no stress at all. Luckily we were taught to cook, sew and cheat our budget to make ends meet. We survive ......live nicely and here are some tips for others in this boat.

Monday, September 22, 2014

Wednesday, September 17, 2014

How to keep from tripping with loose sandals

I love sandals especially just for around the house because hello sewing and bare feet do not mix. I am always dropping pins and just because his luck ran that way, my dad would always be the one to get one jammed in his foot. However lately due to a bad leg sometimes my foot drags or I have to keep it locked and that means lifting it flat footed and if your sandals are loose very easy to catch it on a rug or step or whatever.

Very nice sandals but as you can tell way too loose. I can either walk with toes clenched around the strap (very uncomfortable) or pray I don't catch it on the rug, lose my balance, fall sideways, luckily landing on a chair and hitting the table, knocking over the glass that I set on the edge of the sewing table because my hands were full and I had not tightened the lid and spilling lemonade on my sewing machine. I am very, very familiar with Murphy's law. Luckily the lid was loose but still on so no damage. So time to fix the problem.

Luckily these seem fairly easy to do first thing was to take care of the plastic comfort slide. I did not want to remove it so I trimmed it instead.

I used a thimble to help push the needle through the leather and made sure the stitches were small and pulled tight. Also to prevent possible irritation make sure the knot beginning and ending are in the front.

Very nice sandals but as you can tell way too loose. I can either walk with toes clenched around the strap (very uncomfortable) or pray I don't catch it on the rug, lose my balance, fall sideways, luckily landing on a chair and hitting the table, knocking over the glass that I set on the edge of the sewing table because my hands were full and I had not tightened the lid and spilling lemonade on my sewing machine. I am very, very familiar with Murphy's law. Luckily the lid was loose but still on so no damage. So time to fix the problem.

Luckily these seem fairly easy to do first thing was to take care of the plastic comfort slide. I did not want to remove it so I trimmed it instead.

I keep one seam ripper for jobs like this and one for actual seam ripping so I do not dull the blade. You can also use small sharp scissors but I find better control this way. Once I cut all the way around I slice up and remove the piece. To make sure the remaining half does not irritate my foot I use an emery board to smooth the plastic.

I am lucky because in this one you can see the leather loops through instead of sewn directly so I pushed the loop lower and moved the plastic up until I had it in the right place.

I used a thimble to help push the needle through the leather and made sure the stitches were small and pulled tight. Also to prevent possible irritation make sure the knot beginning and ending are in the front.

Here you can see the real difference in height.

Much better fit and more comfortable. If there is no loop then fold the strap and stitch the top and bottom of the fold to make sure there is no gap. In this case you would have to remove the plastic guard. If you slice it carefully you could put it back with a little goop or buy the ones they sell on line.

Monday, September 15, 2014

Patching thin material

My sister has a very nice top made from an orange broomstick skirt that I did for her. Less then a month later she brings it in and shows me large areas of packing tape on the underside holding several tears together.

I was not a happy camper because patching gauzy material is pain in the caboose. Sewing looks ugly, patches are too heavy and heat bond only on the tear leaves the area flat. Then I had one of my weirder ideas. I needed texture and I needed something to match the color and weight.

I put down the heat bond first then pulled a lot of thread into a tangled mess and positioned it over the bonding. There was paper underneath and I used some on top to protect the iron.

I could have left it at that but the first time it was washed the thread would catch and fall of so I used some sheer ribbon that I had left and some more heat bond. Because the sheer mesh will let the adhesive seep through be sure to use the paper and peel off while still hot.

It is not perfect but not as noticeable either. In addition there is no heavy patch to drag the gauze off balance nor is the area all flattened.

I was not a happy camper because patching gauzy material is pain in the caboose. Sewing looks ugly, patches are too heavy and heat bond only on the tear leaves the area flat. Then I had one of my weirder ideas. I needed texture and I needed something to match the color and weight.

I put down the heat bond first then pulled a lot of thread into a tangled mess and positioned it over the bonding. There was paper underneath and I used some on top to protect the iron.

I could have left it at that but the first time it was washed the thread would catch and fall of so I used some sheer ribbon that I had left and some more heat bond. Because the sheer mesh will let the adhesive seep through be sure to use the paper and peel off while still hot.

It is not perfect but not as noticeable either. In addition there is no heavy patch to drag the gauze off balance nor is the area all flattened.

Underwear that fits for the Plus Sized Woman

Having nice underwear makes any woman feel pretty, having underwear that is actually comfortable as well is a blessing and most times extremely expensive once you get into 5x and up. If you look at online shops they average around $14.00 and up, mainly the "and up". My sister and I prefer the high leg cut because nothing makes your day like sitting down and having the circulation in your leg cut off. My sister wanted a higher cut then what she could normally find, then found what she was looking for in the Japanese style loincloth or fundoshi.

Though in this case we wanted elastic not tying. With nothing on the side there would be no binding which would allow for a smoother line and more comfort. So time to experiment. It needed stretch so we found some pretty material at the fabric story. The width of the material depends on you but really 1/2 yard is more then enough and allows for the hemming on the sides. You can make wider if you want whatever is most comfortable for you.

To get the measurement you need one other person besides you. You need four measurements.

This is where it's best to have someone or two someones if you can help you get the correct measurements. The model needs to be wearing tight pants or leggings or if they are family then good fitting underwear. Hold the material in front of you with both hands then have the other person pull it between your legs and back up towards your waist. Do not pull too much but do make sure that there is some stretch to it. Mark the material with a safety pin. This will be the working length of the underwear. If there not another person then pin the material to the persons clothing this is where tight pants work best because they will hold the pin.

A = the waist measurement make sure the tape measurement is snug but not tight.

B= with a safety pin mark the front where the gathers begin just above the pubic bone

C= with a safety pin mark the back where the gathers begin just above where the thigh hits the butt cheek

Now lay the material down and get your measurements. In this case the waist was 84"

The overall length was 43" and width was of course 18" and that is the first rectangle. Figuring that 84"-18"-18" = 48/2=24 that gives you the remaining side. Since the material needs to stretch reduce that by 1/3 and you need side pieces of 16" by 3".

Now for the crotch insert I prefer cotton because it breathes. The bigger you are the more you sweat, that is a fact of life, so while you can get by with polyester I believe that the cotton is better. If you measure from front gather to back gather that tells you how long a piece you need. a quick measurement will give you the width from the center of the crotch and the width from the ends comes from point B measured across the gather.

*****************************************************************************

{This is semi related, while I love the cloth tape measure I also use a Stanley tape measure. It is like having a third hand since it can be extended and locked perfect for large pieces of material. For me especially, I have health issues that prevent bending or crouching and sometimes trying to get a measurement meant I needed to talk someone else through it which is difficult or do it myself then pay later for bending and twisting. For getting inseams and in this case the width for the center of the crotch area I can extend the tape and bend to fit. This works really well when needing to take measurements of a stranger.}

*********************************************************************************

Cut out and pin to the cotton. you will need two layers. This is so you can have clean edges and a stable strong insert. You can of course get by with only one layer I just think two is better.

Sew the edges except for a two inch opening in order to turn the piece inside out. When finished you should have something like this.

Fold in the long edges of the rectangle and sew with a zigzag or multi-stitch zigzag. Then with the larger rectangle folded iron the edge to form a crease same with the insert. Then unfold and center one on the other.

Mark the edges then move the mark in 1/2" and draw a chalk line, when finished you should have the center fold and two chalk lines.

Either by hand, which I prefer or by machine do a running stitch in order to gather the material.

You will start with the center gather pull it in tight then place the insert over and move the edges to match. The walking foot really helps here and keeps the gather nice and tight.

Now I know what you are thinking why didn't I cut back the center instead of gathering the material; wouldn't it be bulky, won't it show? My sister says she cannot feel any bulkiness, It does not show up under your clothes unless you are wearing something skintight and in that case they are way to close to be looking or you have other things on your mind and should be wearing something lacy anyway. {Sorry my pain medicines are making me loopy although trying this with stretch lace may be an option hmmmm.} I have tried to cut out the middle but the problem lies with the angle of the pull of the material and when you do that the sides do not pull flat instead depending on your shape they will become floppy. Remember there are no sides the materials pull is the only thing keeping it in place.

Now you will do the same thing for the ends.

The finished piece should look like the picture below and there is a solid reason for this.

Remember it will be stretching a little when it does this will ease some of the bulk making it less.

Now you have this.

Now it is a simple job to attach the sides to the top.

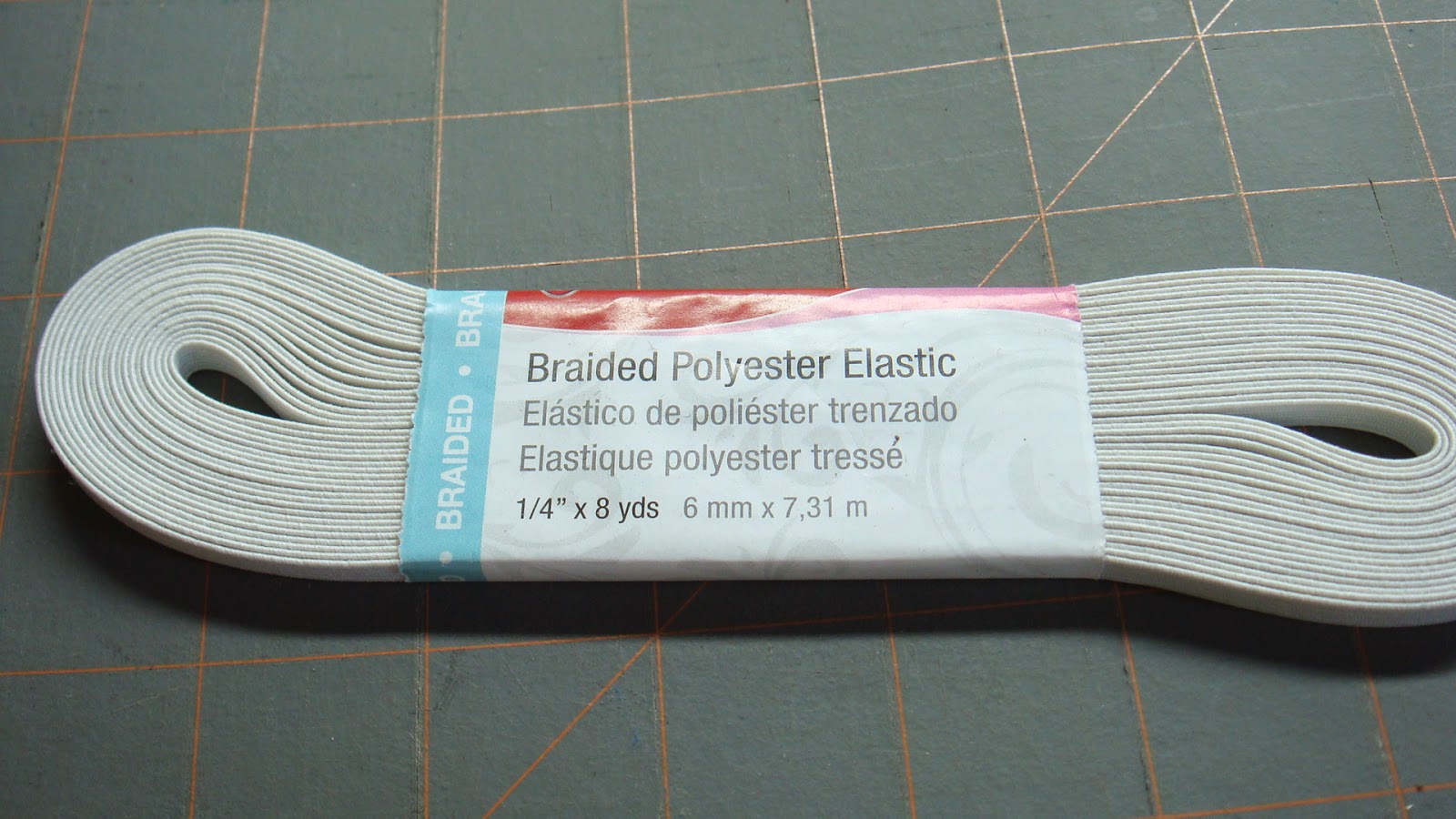

Next is the elastic and this can be done in several different ways. You are going to fold the edge over 1 1/2". Remember the sides are 3" so you will basically be folding in half. You can go with a light weight 1/2" to 3/4" elastic but I feel that it can get in the way of skirt and pants waistbands. What I do is use 1/4" elastic. And because I am a firm believer in S**t happens I prefer to use a double channel and use two pieces of elastic. And back to the math 84" waist. The measurement of the elastic is dependent on it's stretch. Basically I just pulled a piece until it was snug but not circulation cutting then measured it. In this case it was 50 inches which works to about 3/5th of the total. I added an inch for over lap and began to cut the elastic needed.

I did a double channel using a stretch stitch then put in the elastic and closed it off.

When done this is what you have.

Make sure that you have written all the measurements down along with a sample drawing in your notebook. Once you have done one it is easier to mass produce some more.

Tips:

Though in this case we wanted elastic not tying. With nothing on the side there would be no binding which would allow for a smoother line and more comfort. So time to experiment. It needed stretch so we found some pretty material at the fabric story. The width of the material depends on you but really 1/2 yard is more then enough and allows for the hemming on the sides. You can make wider if you want whatever is most comfortable for you.

To get the measurement you need one other person besides you. You need four measurements.

This is where it's best to have someone or two someones if you can help you get the correct measurements. The model needs to be wearing tight pants or leggings or if they are family then good fitting underwear. Hold the material in front of you with both hands then have the other person pull it between your legs and back up towards your waist. Do not pull too much but do make sure that there is some stretch to it. Mark the material with a safety pin. This will be the working length of the underwear. If there not another person then pin the material to the persons clothing this is where tight pants work best because they will hold the pin.

A = the waist measurement make sure the tape measurement is snug but not tight.

B= with a safety pin mark the front where the gathers begin just above the pubic bone

C= with a safety pin mark the back where the gathers begin just above where the thigh hits the butt cheek

Now lay the material down and get your measurements. In this case the waist was 84"

The overall length was 43" and width was of course 18" and that is the first rectangle. Figuring that 84"-18"-18" = 48/2=24 that gives you the remaining side. Since the material needs to stretch reduce that by 1/3 and you need side pieces of 16" by 3".

Now for the crotch insert I prefer cotton because it breathes. The bigger you are the more you sweat, that is a fact of life, so while you can get by with polyester I believe that the cotton is better. If you measure from front gather to back gather that tells you how long a piece you need. a quick measurement will give you the width from the center of the crotch and the width from the ends comes from point B measured across the gather.

*****************************************************************************

{This is semi related, while I love the cloth tape measure I also use a Stanley tape measure. It is like having a third hand since it can be extended and locked perfect for large pieces of material. For me especially, I have health issues that prevent bending or crouching and sometimes trying to get a measurement meant I needed to talk someone else through it which is difficult or do it myself then pay later for bending and twisting. For getting inseams and in this case the width for the center of the crotch area I can extend the tape and bend to fit. This works really well when needing to take measurements of a stranger.}

*********************************************************************************

Cut out and pin to the cotton. you will need two layers. This is so you can have clean edges and a stable strong insert. You can of course get by with only one layer I just think two is better.

Sew the edges except for a two inch opening in order to turn the piece inside out. When finished you should have something like this.

Fold in the long edges of the rectangle and sew with a zigzag or multi-stitch zigzag. Then with the larger rectangle folded iron the edge to form a crease same with the insert. Then unfold and center one on the other.

Either by hand, which I prefer or by machine do a running stitch in order to gather the material.

You will start with the center gather pull it in tight then place the insert over and move the edges to match. The walking foot really helps here and keeps the gather nice and tight.

Now I know what you are thinking why didn't I cut back the center instead of gathering the material; wouldn't it be bulky, won't it show? My sister says she cannot feel any bulkiness, It does not show up under your clothes unless you are wearing something skintight and in that case they are way to close to be looking or you have other things on your mind and should be wearing something lacy anyway. {Sorry my pain medicines are making me loopy although trying this with stretch lace may be an option hmmmm.} I have tried to cut out the middle but the problem lies with the angle of the pull of the material and when you do that the sides do not pull flat instead depending on your shape they will become floppy. Remember there are no sides the materials pull is the only thing keeping it in place.

Now you will do the same thing for the ends.

The finished piece should look like the picture below and there is a solid reason for this.

Remember it will be stretching a little when it does this will ease some of the bulk making it less.

Now you have this.

Now it is a simple job to attach the sides to the top.

Next is the elastic and this can be done in several different ways. You are going to fold the edge over 1 1/2". Remember the sides are 3" so you will basically be folding in half. You can go with a light weight 1/2" to 3/4" elastic but I feel that it can get in the way of skirt and pants waistbands. What I do is use 1/4" elastic. And because I am a firm believer in S**t happens I prefer to use a double channel and use two pieces of elastic. And back to the math 84" waist. The measurement of the elastic is dependent on it's stretch. Basically I just pulled a piece until it was snug but not circulation cutting then measured it. In this case it was 50 inches which works to about 3/5th of the total. I added an inch for over lap and began to cut the elastic needed.

I did a double channel using a stretch stitch then put in the elastic and closed it off.

When done this is what you have.

Make sure that you have written all the measurements down along with a sample drawing in your notebook. Once you have done one it is easier to mass produce some more.

Tips:

- you can find plenty of pieces in the remnant section of your favorite fabric store so long as it has stretch and is comfortable you can use it. (I intend to try with old t-shirt next)

- always square off the material to make your rectangle. people are not perfect and cutting a small piece of twisty slippery fabric can leave for some major uneven edges.

- not all materials stretch the same. remember what type of stretch the original piece you are getting the measurement from and if the next piece is less or more stretchy adjust accordingly.

- these can be very cheaply made. Even at full price a 1/2 yard will still only cost around $5.00.

- I got 3 1/2 sets of elastic from the one roll of elastic.

Subscribe to:

Posts (Atom)